Al-Mg@PVDF and Al-Si@PVDF composites with enhanced combustion and energy release characteristics

Published 17 June, 2025

With increasing demand for high-performance energetic materials in defense applications, improving the combustion efficiency and energy release characteristics of metastable intermolecular composites (MICs) has become a critical research focus. In a recent study published in Defence Technology, a team led by Professor Lin Jiang from Nanjing University of Science and Technology reported findings on the combustion and energy release properties of AI-Mg@PVDF and AI-Si@PVDF composites.

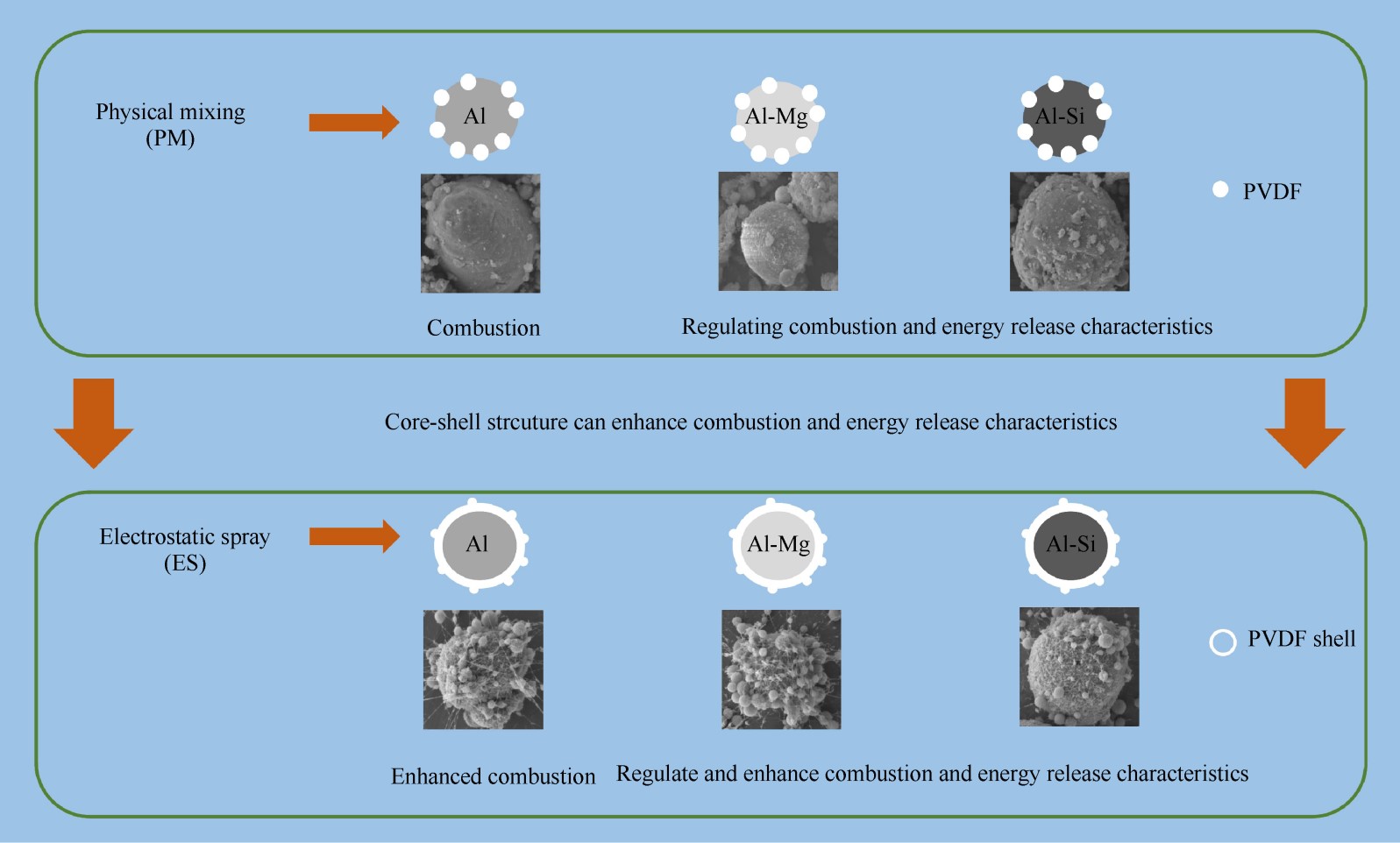

We set out to investigate the differences in combustion and energy release characteristics of metastable intermolecular composite materials composed of aluminum alloys and polyvinylidene fluoride (PVDF) with different compositions,” shares Jiang. “To do that we selected Al-Mg and Al-Si alloys, along with pure aluminum powder for comparison, and prepared PVDF-coated metal particle composites and their physical mixtures."

The researchers employed a systematic approach comprising scanning electron microscopy (SEM), energy-dispersive X-ray spectroscopy (EDS), X-ray diffraction (XRD), combustion performance experiments, closed vessel pressure tests, and simultaneous thermogravimetric-differential scanning calorimetry (TG-DSC) to analyze the morphology, compositional structure, combustion performance, energy release characteristics, and thermal reactivity of the fabricated composites and their combustion products.

“Our results indicated that the PVDF-coated metal particles prepared by the electrostatic spray method (ES) exhibited a distinct core-shell structure, with metal particles in close contact with the PVDF matrix,” shares Jiang. “Compared to the PM blended materials, the ES composites demonstrated superior combustion performance and energy release characteristics during combustion.”

Analysis of different metal fuel systems under identical preparation conditions revealed that Al-Mg and Al-Si fuels modulate the combustion and energy release properties of aluminum alloy-PVDF MICs through two distinct pathways.

Contact author details: Lin Jiang, School of Safety Science and Engineering, Nanjing University of Science and Technology, Nanjing 210094, China. ljiang@njust.edu.cn

Funder: National Natural Science Foundation of China (NSFC, Grant Nos. 52176114 and 52306145), Natural Science Foundation of Jiangsu Province (Grant No. BK20230929), China Postdoctoral Science Foundation (Grant No. 2023M731693), Fundamental Research Funds for the Central Universities, Grant No. 30924010505 and Jiangsu Funding Program for Excellent Postdoctoral Talent.

Conflict of interest: The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

See the article: Zhanjun Yang, Hao Liu, Mi Li, Xiaoqian Wang, Oisik Das, Zhong xuan Han, Lin Jiang,

Al-Mg@PVDF and Al-Si@PVDF composites with enhanced combustion and energy release characteristics,Defence Technology,Volume 48,2025,Pages 1-25, https://doi.org/10.1016/j.dt.2024.12.020