Study of multi-frequency ultrasonic thawing on pork: Thawing rate and quality properties

Published 16 July, 2023

Pork is a highly nutritious food offering a balanced combination of essential amino acids, unsaturated fatty acids, minerals, and vitamins. However, when pork is stored at room temperature, it becomes vulnerable to microbial contamination, leading to a decline in its overall quality. To address this issue, freezing has become a common preservation method, effectively extending the shelf-life of meat by inhibiting microbial growth and biochemical reactions.

Frozen meat must be thawed before further processing or consumption. This, however, greatly impacts the flavor and quality of the meat. Currently, traditional methods of meat defrosting include air defrosting, flow water thawing, microwave thawing, warm saline thawing, among others. These methods are widely used due to their simplicity and convenience. However, they do have certain limitations, such as slow thawing efficiency, discoloration, loss of nutrients, and damage to muscle tissue structure.

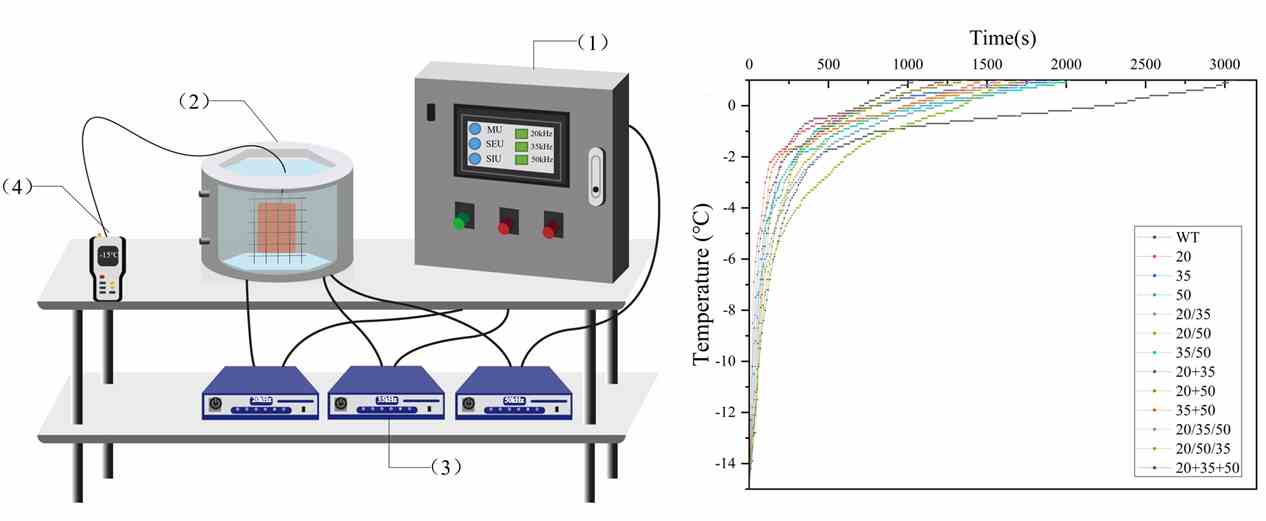

To that end, a team of researchers from China and Australia conducted a study to investigate the effects of ultrasonication on the thawing rate, physicochemical properties, water migration, distribution, and microstructure of pork. The study explored different frequency combination modes, including mono-, dual-, or tri-frequency sequential and simultaneous modes.

“We found that ultrasonic-assisted thawing significantly enhanced the thawing rate and reduced the thawing time by 26.72–64.99% compared to conventional water immersion thawing. Moreover, it effectively suppressed lipid oxidation in the thawed pork samples,” shared the study’s lead author, Zhongyuan Chen.

When considering the quality attributes of frozen pork, the samples thawed using the combined tri-frequency sequential ultrasound mode (TSEU) at 20/50/35 kHz showed superior water retention, as indicated by lower thawing loss and cooking loss. These samples also had improved physicochemical quality, characterized by reduced hardness, increased tenderness, and lower TBARS values, indicating lower lipid oxidation.

“Microstructure analysis revealed that the pork thawed at these frequencies closely resembled the microstructure of fresh meat, exhibiting a well-distributed and regular arrangement of muscle fibers,” added Chen.

The team reported their comprehensive findings in the KeAi journal Food Physics.

Image: Schematic diagrams of the multi-frequency ultrasound device. (1) Control panel; (2) Ultrasonic bath; (3) Ultrasonic generators; (4) Digital thermometers, and thawing curve under different thawing methods.

Contact author details: Lina Guo, School of Chemistry, The University of Melbourne, Parkville, Victoria 3010, Australia. E-mail address: lina.guo@unimelb.edu.au

Funder: This work was supported by the Key Research & Development Program (Modern Agriculture) of Jiangsu Province (BE2018368).

Conflict of interest: The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

See the article: Zhongyuan Chen, Yaoyao Wang, Lina Guo, et al., Application of multi-frequency ultrasonic thawing on pork: Thawing rate, quality properties and microstructure, Food Physics, Volume 1, 2023,100002, ISSN 2950-0699, https://doi.org/10.1016/j.foodp.2023.100002.