New, fully biodegradable cellulose membrane proves effective in oil-water separation

Published 22 June, 2022

Oil spills and industrial pollution pose a huge threat to the ecological environment. Concerns over safety have seen an increased focus on improving the filtration of oily wastewater; for example, during the treatment of sewage. Membrane separation technology offers a promising and efficient option for treating that wastewater, particularly with its low energy consumption. However, it remains a challenge to find low-cost, strong and environmentally-friendly composite membranes that can achieve a high level of separation.

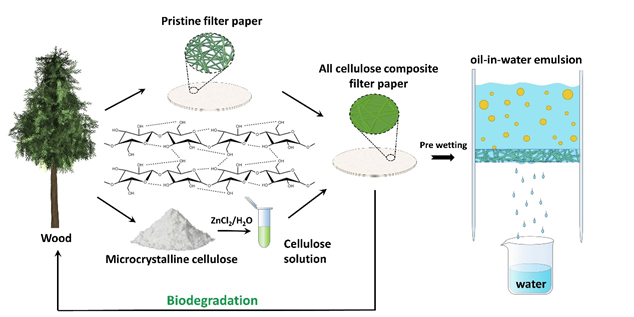

A group of researchers at Shanxi Institute of Coal Chemistry (part of the Chinese Academy of Sciences - CAS) have developed a new and improved method using two different cellulose materials. Their process allows them to obtain membrane materials for oil-water separation that are ‘all cellulose’ (cellulose with two or more different crystal forms).

Importantly, as they outline in their study results, published in the KeAi journal Green Energy & Environment, their membrane is friendly to the environment.

According to Prof. Tiansheng Deng, the paper’s corresponding author: “Oil-water separation membrane materials that have been widely used in recent years include vinylidene fluoride (PVDF), polypropylene (PP), polyacrylonitrile (PAN), nylon or their composites. However, these polymers are non-biodegradable and put further pressure on the environment.”

To solve this problem, Prof. Deng and his group chose degradable cellulose derived from plants as a raw material and then bonded it with commercial cellulose filter paper, which is low in price and porous. They found that a large number of nanopores appear in the modified cellulose filter paper, which improve the membrane’s barrier against oil droplets. When their separation membrane comes into contact with water, a cellulose hydrogel is formed that effectively separates oil-water mixture and oil in water emulsion.

Prof. Deng adds: “Cellulose chains are tightly bonded by a hydrogen bond, with few defects, and the mechanical properties of the material are greatly improved. The high dry and wet mechanical properties of the membrane extend the ways in which it can be applied and help it to remain stable when used in water. We believe this is an important step forward in the treatment of pollution.”

Image: The CLOSED LOOP PROCESS OF the DEGRADABLE CELLULOSE OIL-WATER SEPARATION MEMBRANE. Credit: Institute of Coal Chemistry (CAS).

###

Contact the author: Tiansheng Deng, dts117@sxicc.ac.cn