New in situ coring and testing system for deep mining makes “living” samples a reality

Published 14 February, 2022

With the gradual depletion of shallow energy resources, such as coal, ore, oil and natural gas, the focus has shifted to mining at depths of up to 5,000 metres. However, the transformative technologies available to work that far below the Earth’s surface are currently fairly limited.

For example, engineers extracting rock samples to evaluate deep resources are currently unable to preserve the in situ environmental conditions, resulting in the loss of valuable information on morphology, parameters, liquids, gases and microorganisms.

According to Prof. Heping Xie of China’s Shenzhen University, “this lack of in situ information is hindering deep resource development, making it difficult to achieve safe, efficient, and economic exploitation. However, due to the complexity of these deep environments, where pressure often exceeds 100 MPa and the temperature 150 ℃, finding a solution hasn’t been easy.”

It appears that Prof. Xie and his team may have done just that. In a study published in the KeAi journal Petroleum Science, they outline a ground-breaking process that has the potential to obtain and test "living" samples from the deep Earth.

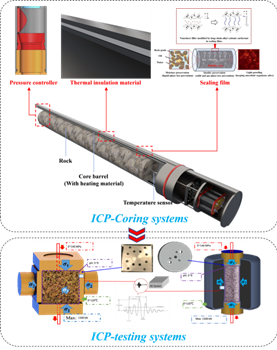

He explains: “The ICP-Coring coring system we’ve developed obtains in situ rock samples, transfers them to a testing system, and then analyses them in a reconstructed environment. This makes it possible to obtain more accurate parameters than those currently measured with ordinary cores.”

Their system includes a pressure controller, active thermal insulation module, insulation layer and sealing film. The ultimate bearing strength is 100 MPa for pressure preservation, and it can realise a temperature retention accuracy of 0.97%.

Prof. Xie says: "The CH4 and CO permeabilities of the optimised sealing film are as low as 3.85 and 0.33 ppm/min, respectively, while the light transmittance is reduced to 0%. We’ve also achieved a pressure and steady-state temperature accuracy for reconstructing the in situ environment of the transfer and storage system of up to 1% and ±0.2. In addition, the error recorded for the noncontact sensor ring made of low-density polymer is less than 6% of that of the contact test.”

He adds: "This new in situ coring and testing system will fill in the gaps in the principles, technology and equipment of deep in situ rock mechanics and enable further development of deep-earth, deep-sea, and deep-space prospecting and coring technology.”

###

Contact the corresponding author: He-Ping Xie, xiehp@scu.edu.cn